Parth Valves And Hoses LLP is pleased to offer top-of-the-line products in pipeline flow control. The PARTH VALVE AND HOSES ‘s Butterfly Valves have been developed with extensive application, design and manufacturing expertise. These products are produced by employing modern manufacturing practices under a robust quality assurance system. These practices ensure consistent product quality and dependable performance. The PARTH VALVE AND HOSES ‘s Butterfly Valves have been designed to include state-of-the-art features that are described in this bulle

TECHNICAL DATA

- PARTH VALVES AND HOSES has extensive experience in manufacturing Butterfly valve in following Types, Wafer type design, lug type, Sanitary type, Double flange design , metal seated design.

- Size :

1. 1” up to 24“ (DN 25 up to DN 600) hygienic series. (From DN 700 to DN 4000 on request)

2. 1.5” to 48” (DN 40 up to DN 1200) Industrial series

- Pressure Rating : PN10 (hygienic series)

ASME 150# to 300#

- Materials : Cast Iron, Carbon Steel, stainless Steel (SS304, SS316, SS316L) ,Duplex Stainless Steel, Super Duplex Stainless Steel, Alloys, Hastelloy, Inconel.

- Design Standard : API 609 / BS EN 558-1, / ISO 5752

- Pressure / Temperature Rating : ASME B 16.34

- Test (Inspection) Standard : API 598.

- Operation : Lever, Gear, Actuator (Pneumatic and Electric Motorized)

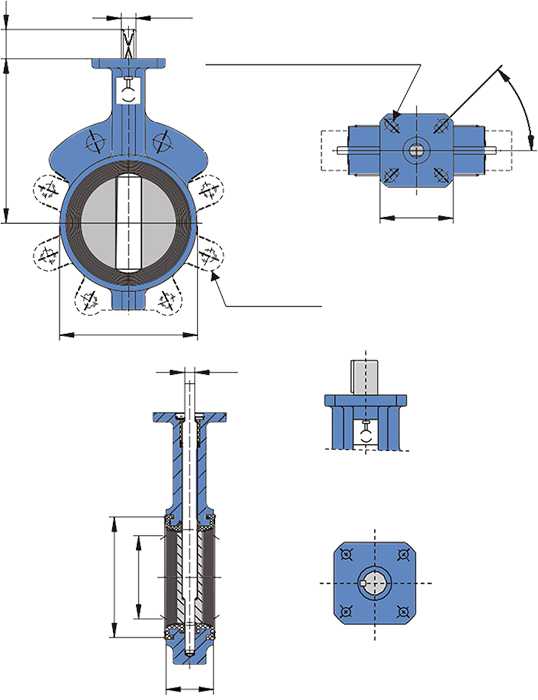

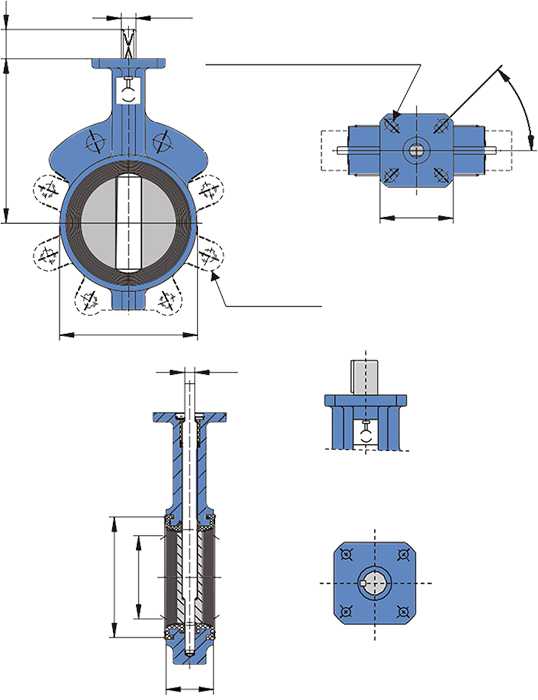

- Butterfly Valves are available in four different types’ versions :

• Centre Line

• Double Offset

• Tripple Offset

- Special Service : almost all PARTH VALVES AND HOSES can designs in a special version as per customer’s Requirements. In this case, all the material details and technical features are given by the Customer & all Design aspects from us.

SALIENT FEATURES

- Stem connection available in standard PARTH VALVES AND HOSES sizes or optional sizes to match standard secondary top plate drilling

- Nylon PA 12 coated disc option ensures excellent corrosion resistance to several chemical media. The hard, non-porous sintered polymer has very low hygroscopicity and is suitable for use in drinking water and non- alcoholic foodstuffs.

- Stem connection available in standard PARTH VALVES AND HOSES sizes or optional sizes to match standard secondary top plate drilling

- Unique “Center-Lock” seat design virtually eliminates any seat movement during the seating and un-seating of the disc.

- Heavy duty square-grooved seat design with molded O-ring seals to serve as flange gaskets. EPDM and Buna-N seats are peroxide cured to yield the best elastic properties of the elastomer.

- High strength disc with hand polished disc edge and hubs.

- Heavy duty one-piece body with extended neck for 2” piping insulation. Standard coating is two coats of hard, Zinc-rich epoxy for excellent corrosion resistance.

- Unique stem retention system to provide blow-out proof stem and easy assembly and disassembly of valve.

APPLICATIONS

- Food Industry

- Dairy Industry

- Brewery Industry

- Pharmaceutical Industry